General

· Physical envelope: 2.176” Dia x 1.66” L

· Weight: approximately 4.25 oz.

· Specially designed for electronics box cooling, such as avionics, radar, electronic counter-measures, displays, and communications equipment in aircraft, ground and shipboard applications

· Custom mounting configurations, such as flanges or servo rings and synclamps, are available

Materials and Finishes

· All aluminum components finished with a chemical conversion coating per MIL-C-5541, top coat of lusterless black enamel, color #37038, per Federal Standard 595 conforming to TT-E-489 Type B

· Corrosion-resistant stainless steel shaft and hardware

· Impeller runs on two high-precision, double-shielded, stainless steel ball bearings (ABEC Class 5) with an integral lubricant reservoir for a long, maintenance-free life

· Motors have stator winding insulation which is rated for continuous duty for Class F

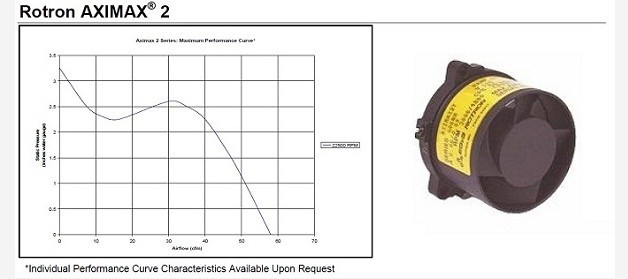

AC Powered Units

· 3-phase and 1-phase permanent-split capacitor motor designs

· Fixed speeds (performance) based on input frequency.

· Meets or exceeds the requirements of MIL-B-23071 and other applicable U.S. military and commercial aerospace specifications

· Max free delivery airflow of 6 CFM at 50Hz, 8 CFM at 60Hz, 60 CFM at 400 Hz

· Ambient temperature range: -54°C to 125°C

· Acoustic levels as low as 55 dBA

DC Powered Units - E.C.D.C. ®

· Brushless permanent magnet design (Electronically Commutated DC)

· Speed (performance) fixed by input voltage

· Meets or exceeds the requirements of MIL-B-28873 and other applicable U.S. military and commercial aerospace specifications

· Max free delivery airflow of 59 CFM

· Ambient temperature range: -54°C to 100°C

· Acoustic levels as low as 55 dBA

Optional DC-AC Inverters and AC-DC Converters for AC Powered Models

BATAC®Inverter Driven Units

· AC square wave fans are driven from a DC power source through a BATAC® Inverter.

· Low cost alternative when multiple fans are used in a single application or area.

· Allows for greater than 100 VDC input voltage

DELTAC®Converter Driven Units

· DELTAC®Converters allow high frequency (typically 400Hz) fans to be driven by variable frequency (typically 360-800Hz) power or low frequency 50/60 Hz power to obtain the higher frequency performance

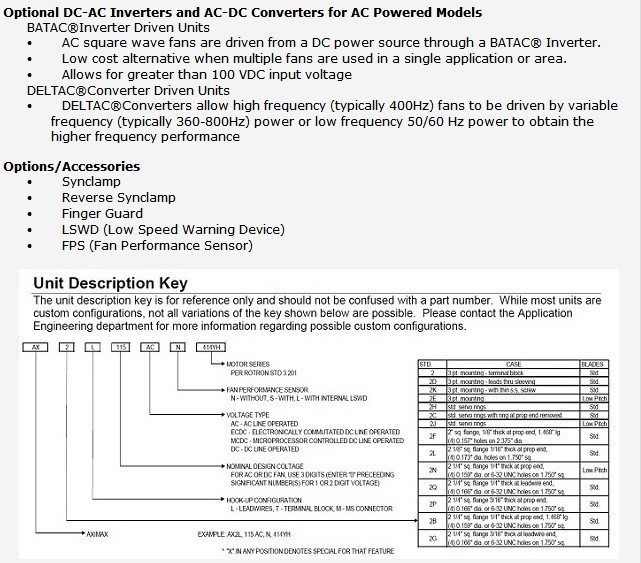

Options/Accessories

· Synclamp

· Reverse Synclamp

· Finger Guard

· LSWD (Low Speed Warning Device)

· FPS (Fan Performance Sensor)